BRICKFIELD, SHED, KILN, &C.

BY

ONE OF THE AUTHORS OF “ENGLAND’S WORKSHOPS.”

COMPRISING

LONDON:

GEORGE ROUTLEDGE AND SONS,

BROADWAY, LUDGATE HILL.

1866.

LONDON

R. CLAY, SON, AND TAYLOR, PRINTERS,

BREAD STREET HILL

Every human being born into the world will find that happiness mainly depends upon the work that he does and the manner in which it is done.

Those who imagine that the necessity for labour is only an evil must be either grossly ignorant or wilfully wicked.

Whoever wastes his life in idleness, either because he need not work in order to live, or because he will not live to work, will be a wretched creature, and at the close of a listless existence will regret the loss of precious gifts and the neglect of great opportunities.

Our daily work, however common or humble it may seem, is our daily duty, and by doing it well we may even make it a part of our daily worship.

For these reasons the choice of a trade is a most important event in every boy’s life, and it is no less difficult than important, because when a boy has just left school he seldom knows much about the operations of any trade, and cannot be expected to express any preference[iv] for one more than another. Whether this book will be of any use in this respect, by directing attention to some of the principal industries of the country in which we live, must after all depend upon the tastes of each particular reader; but it may at all events claim to be useful in making known what are the operations necessary to some of our great manufactures, and in explaining the method of using the tools employed by those engaged in them.

A volume like the present can scarcely be said to have an Author, since much of its contents must necessarily be the work of the compiler, who condenses the valuable material supplied by other writers, and adapts it to his purpose. It is impossible that any great part of the matter can be original; and in some parts of the following pages the writer has found it altogether inexpedient to change even the manner of those who are regarded as the principal authorities on scientific subjects. He believes, however, that even where he has borrowed, he has borrowed with some discretion. Whether he has succeeded in explaining and simplifying the reader will be able to judge.

BRICKFIELD, SHED, KILN, &C.

It would be very difficult, and perhaps impossible, to discover at what time in the history of the world the art of brickmaking was first practised. In the earliest records of the human race the making of bricks is mentioned; this was part of the labour imposed upon the children of Israel, when they were in captivity in Egypt, and bricks of excellent quality are found in some of the most ancient buildings, the remains of which have been discovered. Though uncivilized nations, and even some which had made[2] great progress in civilization, but lived in very warm or exceedingly cold climates, frequently built dwellings of wood, of wattles or strips of trees and branches covered with clay and lime, and of rough stone and earth; and though whole tribes lived and still live under tents, or in mere log huts and wigwams, or lodges made of the skins of animals, the manufacture of bricks formed of clay, and either burnt with fire or dried in the sun, is amongst the oldest of all known trades. In our own day it has arrived at such perfection and the varieties of bricks and tiles are so great in order to provide for the great diversity in buildings, that it is one of the most important branches of English industry.

We learn from the Bible that burnt bricks were used in building the Tower of Babel, and from early historians, as well as from recent discoveries, we know that they were also made for the walls of Babylon. The bricks of the ancient Egyptians were made of clay tempered with water and mixed with chopped straw, and afterwards dried in the sun, and the labour of the Israelites was made more severe by their being compelled to find straw for themselves. In Rome both burnt or kiln-dried bricks and those dried in the sun were employed, and though at a later date the art of brickmaking seems to have fallen into disuse, it was revived again in Italy after some hundreds of years. The trade seems to have been brought to England by the Romans, and many of the most ancient buildings in this country are made of very fine brickwork, though, till the reign of Elizabeth, only large mansions were so built, the common houses being formed of frame-works of timber filled in with coarse plaster supported by laths of wood.

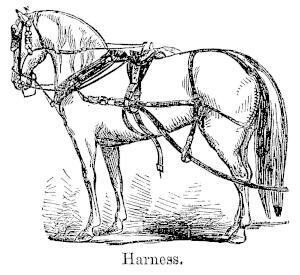

There are few more interesting sights than a brick-field[3] in full work with its great sheds, its horses going slowly round and round in the mills, grinding the clay which has been dug out of the deep pits; its great stacks covered with hurdles and screens made of reeds and its immense kilns, so cleverly and evenly built, where the smoke rises lazily from the dull fires by which the drying or burning is completed.

Clay Mill.

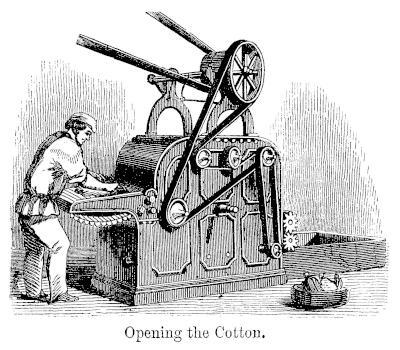

The methods of brickmaking differ considerably in various parts of England, but that which we most commonly see in practice near London will very well represent them all, and it is this which will now be described. The earth used for making bricks is found after digging till the labourers reach the loamy soil lying just above that blue clay which is known as London clay; and this earth is known as strong clay, mild clay, and malm, and this earth[4] requires preparation by mixing with them chalk and the dust of burnt ashes from the dust bins. These burnt ashes the brickmakers call “breeze.”

The chalk mill and the clay mill are placed close together on large mounds, high enough to allow the “malm” (which is a mixture of chalk and clay ground to a thin paste) to run down to the brick earth. The chalk mill is a round trough where the chalk is ground by heavy wheels fitted with spikes on their tires or hoops, and turned by one or two horses. The trough is supplied with water from a pump, and the chalk, as it is ground, runs off by a wooden gutter into the clay mill, where it is again stirred and ground till it mixes with the clay; the mixture then runs through a grating and through other gutters to the brick earth, which has been placed in heaps to receive it.

Hack Barrow. Barrow.

When the earth is mixed in this way, it becomes brick-clay, and is taken in barrows up a sloping board, to the pug mill. The pug mill is a great tub, the top of which is larger than the bottom, and in the centre of it there revolves an upright iron shaft fitted with knives. These knives cut and break the clay as it passes through the mill, and they also force it downwards till it reaches the bottom, where it[5] passes through a hole on to a machine called the Cuckhold, which is a sort of table containing a trough where the clay is cut into lumps ready for the moulder.

Pug Mill.

Barrow for carrying baked Bricks.

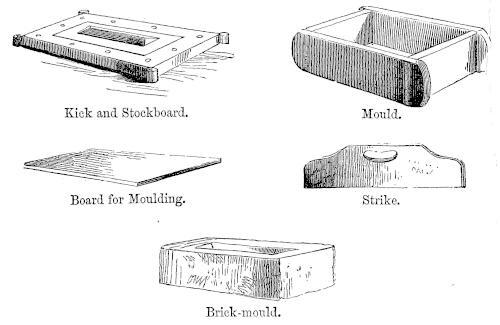

Kick and Stockboard. Mould. Board for Moulding. Strike. Brick-mould.

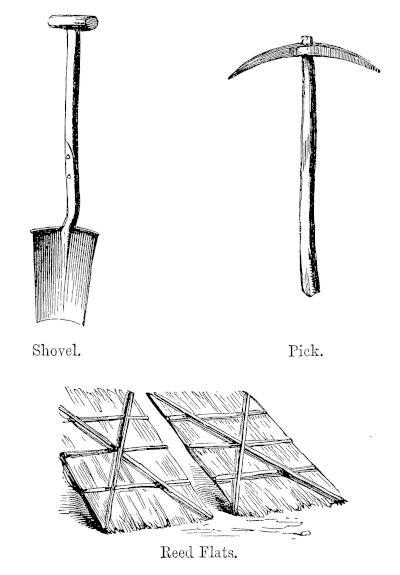

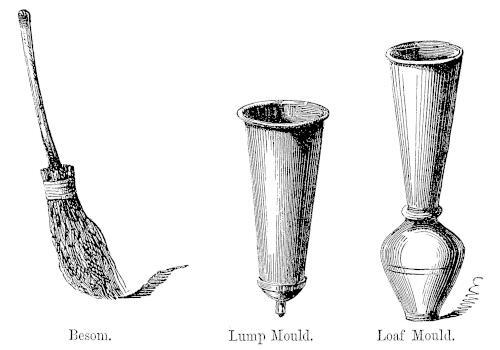

The moulder who shapes the clay into bricks uses moulding sand,—a peculiar sort of sand brought from the[6] bed of the river, and spread out in the sun, where it is turned over and over till it is quite dry. It prevents the clay from shrinking, gives a harder surface to the bricks, and prevents them from sticking to the mould, or to each other; it also gives the London bricks their grey colour. The moulder stands at the moulding stool, which has a rim at each end to keep the moulding sand from falling off, and has a stockboard, which forms the bottom of the brick-mould, and a page, or two iron rods nailed at each end to wooden rails, used to slide the raw bricks from the moulder to the place from which the “taking-off boy” takes them to place on the “hack barrow,” by which they are carried away. The moulder is served with the lumps of clay by the “clot moulder.” The “brick-mould” is a kind of box[7] without top or bottom, and the moulder dashes the tempered clay into the mould with sufficient force to make the clay completely fill it; after which the superfluous clay is removed from the surface of the mould with the strike. The brick is then turned out on to a pallet or board, on which it is wheeled by the boy to the “hack ground,” where the bricks are built up to dry in low walls called “hacks.” The brick moulds are made of brass or iron, and often of wood.[8] Sometimes the bricks are dried on a floor under a shed, but often in the open air, where they are covered with straw, reed-flats, or canvas and tarpauline screens, to protect them from wet, frost, or excessive heat. The bricks are afterwards burnt either in “clamps” or in “kilns.” In clamp burning the bricks are built up close together, and the bottom ones only are heated with burning breeze or cinders, the heat spreading to those at the top. A kiln is a sort of large chamber in which the bricks are loosely stacked with spaces between them for the heat to pass through, and they are baked by fires placed either in arched furnaces under the floors of the kiln, or in fire holes made in the side walls. The kilns are built of various shapes, and one of the principal arts in the trade of the Brickmaker is to construct them that the heat may be properly distributed, and the bricks equally and thoroughly baked.

Shovel. Pick. Reed Flats.

MASONS AT WORK.

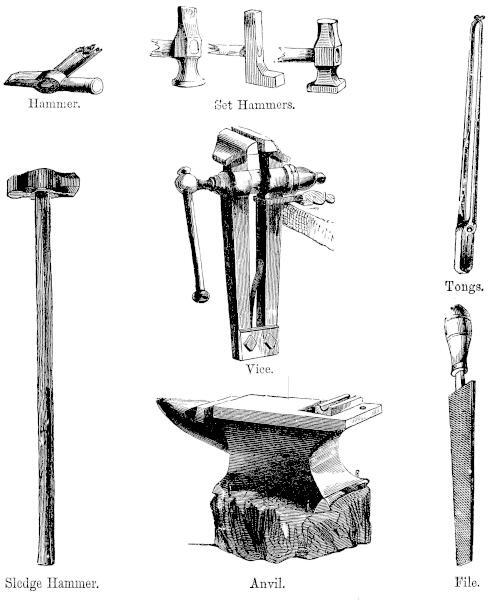

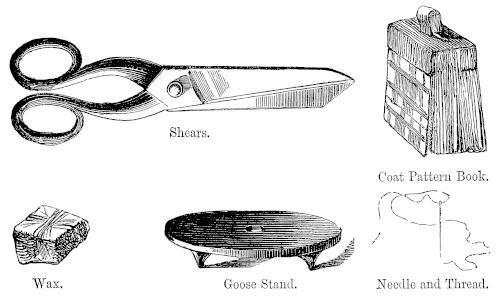

Having already given a description of the way in which bricks are made, we come to the work of the Mason, whose duty it is to prepare the stone work used in building and for other purposes. In the mason’s trade great skill is[10] required, as well as some hard manual labour, since he has to cut the stones for arches, windows, columns, cornices, and porches, into various shapes; and to fit the separate pieces with perfect accuracy, that the Builder or the Architect may be able at once to set them in their proper places. The business of the monumental mason, who erects pedestals for statues, tombs, and ornamental structures in parks and gardens, is generally distinct from that of the builder or architectural mason, although many of the same tools are used in both trades.

The stone used by the mason is of various kinds, and is brought from different parts of the world; but our own country contains stone of nearly every sort which can be well employed in ordinary building. Granite comes principally from Scotland, though a smaller quantity is brought from Ireland; red and white sandstone is plentiful in Yorkshire, Lancashire, and Derbyshire, as well as in Scotland and Ireland; a sort of slate stone is found in Wales; and the most common building stone, which is called limestone, or free-stone, is brought from several counties in England, where it is constantly worked. The stone is generally found under the surface of the earth, and the places from which it is dug are called quarries; the business of quarrying being to extract from the ground, or from the sides of rocks, large masses of stone or marble.

When these lie directly under the ground, the earth at the top is removed, and the stone is afterwards separated into blocks and lifted out by machinery; but it is sometimes necessary to mine for the stone by making galleries underground, and leaving pillars to support the earth above them. In large quarries, the earth at top is first removed, and the first layer of stone, which is generally of a common[11] sort, is broken or blasted with gunpowder, and afterwards taken away. The lower layers of stone are then divided by wedges driven into them, until they split in the required direction; the blocks are afterwards made of a regular square, by a tool called a kevel, pointed at one end and flat at the other, and are then lifted by cranes on to low waggons, upon which they are drawn away. It is the business of the mason to work these stones, which are to be used in building, into their required shape; but before the mason receives them the stone cutter hews and cuts the large blocks roughly into the form in which they are wanted; and when the block is to form top of a doorway, part of a cornice, or any other portion of a building where ornament is necessary, the carver executes these ornaments, and cuts the stone into a pattern of fruit, flowers, or figures.

Peck or Point. Stone Axe.

When the stone is valuable it is sent from the quarry to the mason’s yard, or to the building where it is to be used in large blocks, and there cut into slabs or thin pieces called “scantlings,” of the required size, with a stone[12] mason’s saw (see large cut). This saw differs from those used in other trades because it has no teeth. It is a long thin plate of steel slightly jagged on the bottom edge, and fixed in a frame; and being drawn backwards and forwards in a horizontal position, cuts the stone by its own weight. To make this the easier, a heap of sharp sand is placed on a sloping board over the stone, and water trickling upon it from a barrel washes it into the cut made by the saw. In large establishments the sawing of the stone is often effected by steam machinery. Some of the freestones are so soft as easily to be cut with a toothed saw, worked backwards and forwards by two persons. The tools used by the mason are the peck or point for chipping the surface of the stone, the stone axe for breaking the irregular portions from the block, the iron mallet and beetle, for breaking pieces from the edge of the slab or driving in wedges.

Wooden Beetle. Wedge. Iron Mallet.

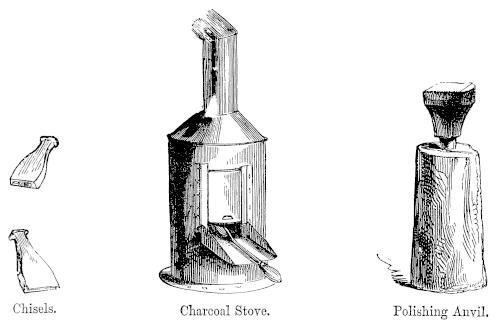

Rubber. Mallet. Brush. Chisels.

The tools used for cutting stone are the mallet and chisels of various sizes. The mason’s mallet differs from that used by other workmen, being of a sort of half pear[13] shape, and with a short handle only just long enough to allow it to be firmly grasped in the hand. The rubber is used for smoothing the surface of the stone, after it has been worked by the tools; sand and water are placed on the stone, and the rubber is pushed backwards and forwards for the purpose of grinding the face of the slab to a smooth surface; another block of stone is sometimes applied[14] to the same purpose. In London the tools used to work the faces of the stone are—the point, a very small chisel only about a quarter of an inch broad at the cutting edge; the inch tool, which is a broader chisel; the booster, broader still; and the broad tool, which is three inches and a half wide: beside these, there are tools of the same kind for working mouldings and carvings.

Square. Bevel Square. Straight Edge. Trowel. Point.

Besides these cutting tools, the mason uses a banker or bench, on which he places his stone for convenience of working, and straight edges, squares, and bevels, for marking the shapes into which the blocks are to be cut, and seeing that his edges and surfaces are even by trying them as the work proceeds.

The bevel square is a square the stock, or lower part, of which is moveable, so that it may be set to any angle or level as required. Sometimes a pattern called a templet is used for cutting a block to any particular shape, and when the work is moulded, the templet is called a mould. Moulds are commonly made of sheet zinc, carefully cut to the profile of the mouldings with shears and files.

It often happens that the mason has not only to prepare the stone, but to set it in its place in the building, and this is properly part of his work. He then uses the trowel, for applying the composition for cementing the stones together; lines and pins to show whether his edges are straight and square, the square and level for a similar purpose; and various rules for adjusting the stone faces of upright walls.

THE BRICKLAYER.

The Bricklayer has so much to do with the erection of buildings that the Master Bricklayer is generally a Builder; that is, he understands not only brickwork and the building of walls, but also the other trades necessary for completing a house, and can superintend the Mason’s, Carpenters’, and Plumbers’ work.

Of course, the first consideration in building a house is[17] the preparation of the foundations, which are formed in various ways, according to the nature of the soil on which they are laid; unless the ground itself is firm enough to receive the walls, sometimes thick layers of concrete (a sort of mortar) is used, sometimes layers of planking are put down, or even cross beams of timber, and in some cases, where the earth is very loose and damp, timber piles are driven into it on which to lay the foundation. The foundation once laid, the vaults or cellars are built either in the ordinary way, or in a series of arches of various forms; then follow the abutments, the wing-walls, the main-walls, with iron “Bressumers” for supporting those parts of the walls which are above large openings like great doors or shop fronts. The partitions, or interior walls, may be either solid brick or stone, or may be constructed entirely of timber, or they may be frames of timber filled in with masonry or brickwork. Then come the floors, the roofs and roof-coverings, and finally the ceilings and the doors and windows. The materials used in building are principally timber, stone, slate, bricks, tiles, mortar, lime, cement, iron, glass, lead, zinc, colours and varnishes. Those with which the working bricklayer has most to do are bricks, slates, tiles, stonework, cement, and mortar, for these are principally used in making walls and roofs, which is the greater part of his trade. The stone and slate come from the quarries, and we have already seen how bricks are made. Mortar is made in the following way.

1st. The soft chalky stone known as limestone, is calcined or burnt, by exposure to strong heat in a lime kiln; the heat drives off a gas which is contained in it (called carbonic acid gas), and leaves it in a state in which it is known as quick-lime.

2d. The quick-lime is “slaked,” by pouring water upon it, when it swells and becomes very hot, afterwards falling into a fine powder.

3d. This powder is mixed into a rather stiff paste, more water is added, and when a certain quantity of sand is added becomes mortar, and may be used for cementing bricks together.

Concrete is made by mixing gravel, sand, and ground unslaked lime together with water; it is used for foundations, and filling in apertures requiring strength and firmness.

Iron is used by the builder in two different states, as cast iron and wrought iron; the girders for supporting roofs and walls are mostly cast in moulds (see Iron Founder), though both these and other parts of the ironwork used in building, are frequently of iron wrought by hand.

Lead is used by the mason for securing and coating the iron clamps which hold the blocks of stone together; it is also used in the plumbers’ work of a house (see Plumber).

Zinc is used in the manufacture of gutters, pipes, and portions of roofs.

Trowel.

The excavator having dug out the space where the foundation of the house is to be laid, the work of the bricklayer begins, and his tools are the trowel, to take up and spread the mortar, and cut bricks by a sharp blow to the requisite length; then there are the brick axe or hammer, for shaping the bricks to a level; the tin saw for making an incision on bricks to be cut with the[19] axe; the rubbing stone on which to rub the bricks smooth in the parts where they have been cut, and the mortar rake and shovel, for mixing the mortar and cement.

Mortar Rake. Crowbar. Shovel. Brick Hammer. Pickaxe.

The crowbar and pick-axe are the tools used for demolishing old brickwork or clearing out rubbish; the sieve (see large cut) for sifting the lime of which the mortar is made,[20] and the rammer for hardening the ground to render the foundation firm. The raker is used for raking out the mortar from the joints of old brickwork which requires re-pointing, or the joints refilled with mortar.

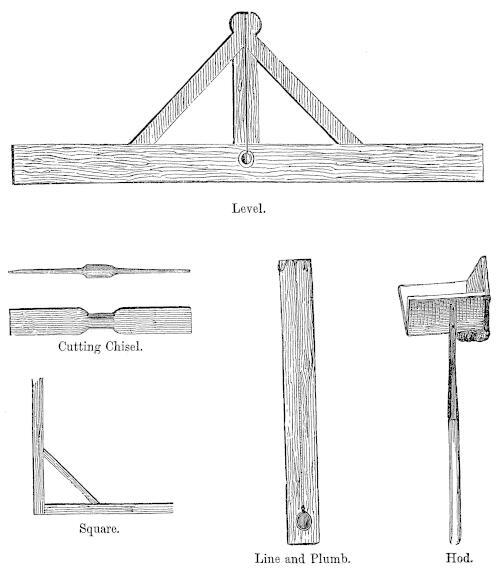

To “set out” the work, which means to measure the spaces, and to keep the lines, curves, and angles, straight and true, the bricklayer uses the square, the level, the plumb-rule; the square shows whether the proper angle has been preserved; the plumb-rule is an upright rule, with a string at one end, to which is attached a leaden ball. If the work is straight on its perpendicular lines, and the plumb-rule be applied to it, this leaden ball will hang exactly in the centre, and swing through a hole in the rule, while, if the work be crooked, it will swing to one side. The level is a rule on the same principle, but for testing horizontal lines, such as a cornice on the top of a wall. The good bricklayer will frequently test his work by these tools, and will also use a line stretched to two pins, to guide him as he builds up his courses of bricks.

The bricks and mortar are supplied to him by a labourer, who carries them in a hod. The labourer also makes the mortar, and builds up and takes down the scaffolding (see large cut). The scaffolding, or that frame of poles and planks erected in front of the building as it is in progress, is constructed of standards, ledgers, and putlogs.

The standards are poles made of fir trees, from forty to fifty feet long, and six or seven inches thick at the butt ends, which are firmly fixed in the ground. When one pole is not long enough, two are lashed together, the rope lashings being tightened by wedges driven in between the coils in a peculiar way. The ledgers are horizontal poles placed parallel to the walls and lashed to the standards; these[21] support the putlogs, or cross pieces, which are about six feet long, one end of them resting in the wall, the other on the[22] ledgers. On these putlogs are fastened the scaffold boards, which are stout boards with pieces of iron hoop placed round the ends, to keep them from splitting.

Level. Cutting Chisel. Square. Line and Plumb. Hod.

A bricklayer and his labourer will lay about a thousand bricks, or two cubic yards of brickwork, in a day.

The tools used for tiling, or placing the tiles on a roof, are the lathing hammer, the iron lathing staff to clinch the nails, the trowel, which is longer and narrower than that used for brickwork, the bosse, for holding mortar and tiles, with an iron hook to hang it to the laths or to a ladder, and the striker a piece of lath about ten inches long for clearing off the superfluous mortar at the feet of the tiles.

WHITEWASHER AND PLASTERER.

When the walls, or what is called the carcase of the house, have been built, the roof made, the inner walls and partitions set up, and the joists and woodwork of the floors laid down, the work of the Plasterer begins. He covers the brickwork and bare timbers of walls, ceilings, and partitions[24] with plaster, to prepare them for painting or papering: he also forms the cornices for ceilings, and the mouldings and decorations, which are usually made in plaster or cement.

The materials which the Plasterer uses for these purposes are:—1st. Coarse stuff, or a paste made with lime, much in the same way as common mortar, and afterwards mixed with hair, which is obtained from the tanner’s yard, after it has been removed from the skins, which are there made into leather. This hair is raked together, and mixed with the mortar, with the hair hook, and a sort of three pronged rake called the drag.

Hair Hook. Fine Sieve.

2d. Fine stuff is made from pure lime, slaked with a small quantity of water, after which enough water is added to bring it to a state in which it resembles cream; it is then left to settle, the superfluous water is poured off, and the mixture is left in a tub, till still more of the water has evaporated, and it is thick enough to use. This stuff is often used for ceilings, and then a small quantity of white hair is mixed with it, to help to make it firmer and more binding.[25] For these finer kinds of plaster it is necessary to use the fine sieve, in order to sift the lime and other ingredients, that only the portion which has been reduced to powder may be retained.

3d. Stucco, which is made by mixing fine stuff with cleaned-washed sand. Stucco is used for house fronts, or other finishing work, which is intended to be painted.

4th. Gauged stuff is used for forming cornices, which run round a ceiling, and for mouldings; it is made by mixing fine stuff with plaster of Paris, which is a fine white powder easily made into a paste, and drying very quickly.

These are only the ordinary materials used by the Plasterer for his work, but there are a great number of cements, which are also applied in the course of his trade; such as Roman and Portland cements, and mixtures made and sold for special purposes of decoration, and the manufacture of ornaments.

These ornaments, such as centre pieces for ceilings, flowers drooping from cornices, bosses or groups on walls, &c. are first modelled in clay, and are afterwards cast in plaster of Paris, placed in moulds made of wax or plaster. In this trade, as in that of the picture frame maker, ornaments are frequently made of papier maché, or the pulp of paper (literally smashed paper), which is a very light, hard, and durable substance for the purpose. The moulds for cornices are made of sheet copper, and are fixed in a wooden frame.

Gauging Trowel. Hammer. Salve. Plasterer’s Hawk. Check Line and Reel.

The various tools used by the Plasterer are shown in the engravings, and the manner in which some of them are used may be seen by the large cut at the commencement of this description of the Plasterer’s trade. The peculiar hammer, with one edge like an axe, is used for breaking[26] down old plaster, and clearing away the mortar from walls and ceilings previous to plastering them afresh; the hawk is a flat board with a handle in the centre, used for holding the plaster or cement, which is being laid on with the trowel. The gauging trowel is the long narrow trowel, used for taking up the fine stuff for cornices and mouldings; these trowels are of various lengths, from three to seven inches. The salve is a sort of small spade, on which the plasterer’s boy lifts the mortar or cement, and places it on the hawk, which the workman holds in his hand; as the salve has a long handle, the plaster can be conveyed to the[27] hawk even when the man is at work on a ladder. The square is similar to that used by the bricklayer, and shows that the corners of the work are straight and even; the compasses are used for measuring distances; the check line for marking out the spaces of the work to be done, and the joint rules for measuring the parts where different portions of the work come together, either at the corners, or in making the mouldings. The set square is also used, for showing that the surface or the line of the work is straight and even.

Joint Rule. Joint Rule. Compasses. Set Square.

When the Plasterer has to cover a ceiling or a partition, he commences by lathing. This is nailing laths over the whole space which is to receive the plaster. Laths are long narrow strips of either oak or fir wood, of various thicknesses; the thicker being used for ceilings, where they have to bear a greater strain than in upright walls.

The next operation is pricking up, or placing the first coat of coarse stuff upon the laths; this is called pricking up, because when the plaster is laid, its whole surface is pricked and scratched with the end of a lath, that it may be rough enough for the next coat. The laying on of this second coat of plaster is called floating, and is performed in the following way. The surface is surrounded with narrow strips of plastering, called screeds, held fast by lines of nails, and these are made perfectly level, by means of the plumb rule (see Builder’s tools), and the use of the hand float. The spaces within these lines of plaster work are then filled with coarse stuff, till the whole forms a flat surface, which is made perfectly level, or “floated” with the floating rule. Other screeds are then formed and filled up in the same way, until the whole ceiling, or wall, forms one flat surface. The operations are the same for ceilings and walls, except that the plumb rule is used for adjusting the level of walls, and the level for that of ceilings.

Square. Modelling Tools. Brush. Floating Rule.

After the work has been brought to an even surface with the floating rule, the Plasterer goes over it again with the hand float, using a little soft stuff to make good any deficiencies.

Hand Float.

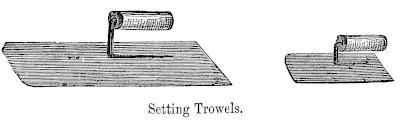

When the floating is about half dry, the setting or finishing coat of fine stuff is laid on, and is first wetted with a brush, and then worked over with a smoothing tool until a fine surface is obtained.

Stucco is laid on with the largest trowel, and worked over with the hand float—being at the same time sprinkled with water—until it becomes hard and solid; after which it is rubbed over with a dry brush. The water has the effect of hardening the face of the stucco; which, after several sprinklings and trowellings, becomes very hard, and as smooth as glass.

Setting Trowels.

The commonest kind of Plasterer’s work is laying on one coat of stuff: when this is done on brickwork it is called rendering, and when on laths it is called laying. When there is a second coat it is called render set, or lath-lay and set: and when it is three-coat work it is called render,[30] float, and set, or, lath-lay, float, and set; this is done in ceilings and partitions with fine stuff mixed with hair; or, when the walls are to be papered, with fine stuff and sand.

Rough stucco is used for finishing staircases and passages in imitation of stone. It is mixed with a great deal of coarse sand, and is not smoothed, the hand float being covered with a piece of felt, so that when it is applied to the stucco the grit of the sand sticks to it and is drawn to the surface, giving the plaster the appearance of rough stone.

Rough casting is used for outside walls, and is done by throwing a layer of gravel, mixed with lime and water, over the second coat of plaster while it is quite wet. In some counties of England, and especially near Nottingham, the plasterers use reeds instead of laths; and even floors are often made by laying down a quantity of coarse stuff upon a foundation of reeds.

These floors are almost as hard as stone, and possess the good quality of being almost always fireproof.

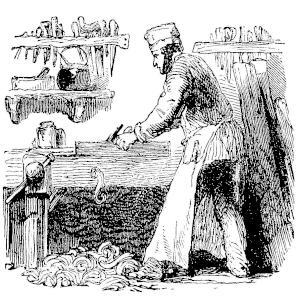

THE CARPENTER’S SHOP.

An account of the tools and implements used for working in wood would scarcely be complete without some remarks upon wood itself, and you can have no better information on this subject than that which has been written by a gentleman[1] who is thoroughly acquainted with the different kinds of timber, and with all the materials used in building.

[1] Mr. E. Dobson, Assoc. Inst. C. E.

If we examine a transverse section of the stem of a tree, we perceive it to consist of three distinct parts; the bark, the wood, and the pith. The wood appears disposed in rings round the pith, the outer rings being softer, and containing more sap, than those immediately round the pith, which form what is called the heart-wood.

These rings are also traversed by rays extending from the centre of the stem to the bark, called medullary rays.

The whole structure of a tree consists of minute vessels and cells, the former conveying the sap through the wood in its ascent, and through the bark to the leaves in its descent; and the latter performing the functions of secretion and nutrition during the life of the tree. The solid parts of a tree consist almost entirely of the fibrous parts composing the sides of the vessels and cells.

By numerous experiments it has been ascertained that the sap begins to ascend in the spring of the year, through the minute vessels in the wood, and descends through the bark to the leaves, and, after passing through them, is deposited in an altered state between the bark and the last year’s wood, forming a new layer of bark and sap-wood, the old bark being pushed forward.

As the annual layers increase in number, the sap-wood ceases to perform its original functions; the fluid parts are evaporated or absorbed by the new wood, and, the sides of the vessels being pressed together by the growth of the latter, the sap-wood becomes heart-wood or perfect wood, and until this change takes place it is unfit for the purposes of the builder.

The vessels in each layer of wood are largest on the side nearest the centre of the stem, and smallest at the outside. This arises from the first being formed in the spring, when[33] vegetation is most active. The oblong cells which surround the vessels are filled with fluids in the early growth; but, as the tree increases in size, these become evaporated and absorbed; and the cells become partly filled with depositions of woody matter and indurated secretions, depending on the nature of the soil, and affecting the quality of the timber. Thus Honduras mahogany is full of black specks, while the Spanish is full of minute white particles, giving the wood the appearance of having been rubbed over with chalk.

The best time for felling trees is either in mid-winter, when the sap has ceased to flow, or in midsummer, when the sap is temporarily expended in the production of leaves. An excellent plan is, to bark the timber in the spring and fell it in winter, by which means the sap-wood is dried up and hardened; but as the bark of most trees is valueless, the oak tree (whose bark is used in tanning) is almost the only one that will pay for being thus treated.

The seasoning of timber consists in the extraction or evaporation of the fluid parts, which are liable to decomposition on the cessation of the growth of the tree. This is usually effected by steeping the green timber in water, to dilute and wash out the sap as much as possible, and then drying it thoroughly by exposure to the air in an airy situation. The time required to season timber thoroughly in this manner will of course much depend on the sizes of the pieces to be seasoned; but for general purposes of carpentry, two years is the least that can be allowed, and, in seasoning timber for the use of the Joiner, a much longer time is usually required.

Properly seasoned timber, placed in a dry situation with[34] a free circulation of air round it, is very durable, and has been known to last for several hundred years without apparent deterioration. This is not, however, the case when exposed to moisture, which is always more or less prejudicial to its durability.

When timber is constantly under water, the action of the water dissolves a portion of its substance, which is made apparent by its becoming covered with a coat of slime. If it be exposed to alternations of dryness and moisture, as in the case of piles in tidal waters, the dissolved parts being continually removed by evaporation and the action of the water, new surfaces are exposed, and the wood rapidly decays.

Where timber is exposed to heat and moisture, the albumen or gelatinous matter in the sap-wood speedily putrefies and decomposes, causing what is called rot. The rot in timber is commonly divided into two kinds, the wet and the dry, but the chief difference between them is, that where the timber is exposed to the air, the gaseous products are freely evaporated; whilst, in a confined situation, they combine in a new form, viz. the dry-rot fungus, which, deriving its nourishment from the decaying timber, often grows to a length of many feet, spreading in every direction, and insinuating its delicate fibres even through the joints of brick walls.

In addition to the sources of decay above mentioned, timber placed in sea water is very liable to be completely destroyed by the perforations of the worm, unless protected by copper sheathing, the expense of which causes it to be seldom used for this purpose.

In modern houses the labours of the Builder, the Mason, and the Plasterer, would be of little use unless they were accompanied by that of the Carpenter, since a very large proportion of every building consists of the woodwork of which its interior structure is greatly composed.

As it is one of the most useful, so the Carpenter’s may be considered the most ancient of trades, for nearly all other handicrafts require the preparation or manufacture of the materials, but the Carpenter originally found his materials in the forest, and at once set to work to construct various articles from the trunks and stems of the trees best suited for the purpose. We can only imagine one trade older than that of the Carpenter, and that is the Tool Maker, and as the earliest tools, or at all events some portion of them, were probably made of hard wood, the Tool Maker may in some sense be said to have been a Carpenter also.

Axe. Adze.

Saw. Compasses. Plumb Rule. Hammer. Square. Mallet.

Strictly speaking, the business of the Carpenter is only with the larger portions of buildings and the rough timber frameworks which support them, and his principal tools are the axe and the adze, for chopping and roughly smoothing timbers; the saw, for sawing beams and planks; the chisel, for making mortis holes for joining beams together, and for[36] cutting and paring wood; the chalk line, a line rubbed with chalk, and used to make a straight line upon a board or beam, to mark the direction in which it is to be sawn; the plumb rule, already described amongst the Builder’s tools; the level; the square; the compasses; all of which have been described in previous trades; the hammer; the mallet, and various sorts of nails. The other tools represented in the engravings belong more properly to the[37] Joiner, but as the trades of the Carpenter and the Joiner are almost always united, we will speak of all the tools as belonging to one business. Carpenter’s work, then, consists of the framing roofs, partitions, and floors, in making the various joints used in beams, ties, rafters, and joists for supporting floors, and the proper way of supporting buildings by posts and girders. The Carpenter requires to be strong and active, that he may properly handle the heavy timbers on which he has to work; he should have a knowledge of the science of mechanics, that he may be able to provide for the strains and thrusts to which the different parts of his work are exposed, and supply the proper means of resisting them; and he should also be able to understand how to make what are called “working drawings,” that he may “set out,” or properly draw a plan of the work he has to do, from the designs of the Architect.

The Carpenter being concerned with the portions of a building which are made of timber, you will be better able to understand his trade by a short description of what these are; and we will then speak a little of the Joiner, whose trade is generally confounded with that of the Carpenter.

First: Partitions, or inner divisions of a building, may be either of brick, stone, or wood; and, in the latter case, they are generally “framed,” or supported in a more solid framework, which should form a portion of the main building, that is, of the outer wall; and should be quite independent of the floors, which should not support, but be supported by them.

Second: Flooring is formed by joists or strong beams of timber reaching from wall to wall, where they rest upon other beams, called wall plates, which are built into the[38] walls themselves. The floor boards are nailed over the upper edges of the joists, and the lower edges receive the laths and plaster, which form the ceilings of the rooms beneath. Large buildings are sometimes fitted with double framed floors, with two sets of joists, and building joists resting on girders; and in superior houses, the wall plates are often supported by “corbels,” or, portions of the timber projecting from the inside of the wall, which prevents the necessity of opening the wall to admit the ends of the joists.

Third: Roofing consists of the roof covering, which is laid upon rafters or slender beams, which are supported by stronger horizontal beams called purlins; and these, again, rest on upright trusses, or strong frames of timber, placed on the walls at regular distances from each other. Upon the strength and firmness of these trusses, and the skill of the carpenter’s work, depends the entire safety of the roof.

Large roofs are supported by cross beams, called collars, or tie beams; and they are further strengthened by an upright pillar in the centre, called a King post, from which slanting beams, called “struts,” support the rafters.

We have now only spoken of common roofs, but there are many roofs of open timber-work in churches and other public buildings, which are wonderful specimens of the skill of the Carpenter and the Joiner. One of these, perhaps the grandest as well as the most ancient, is that of Westminster Hall; but there is one also in the Great Hall, at Hampton Court Palace; and others may be seen in Churches and Halls in various parts of England.

The Joiner, as his name implies, frames and joins together the wooden finishings and decorations of buildings, such as floors, staircases, skirtings, door and window frames, sashes,[39] or, the sliding parts of windows that contain the glass, shutters, doors, chimney-pieces, &c. This work requires much greater nicety and finish than that of the Carpenter, and is brought to a smooth surface with the plane wherever it is likely to be seen, while the carpenter’s work is left rough as it comes from the saw.

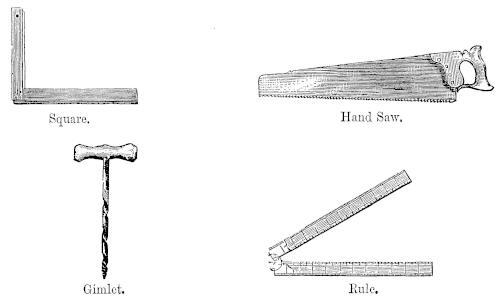

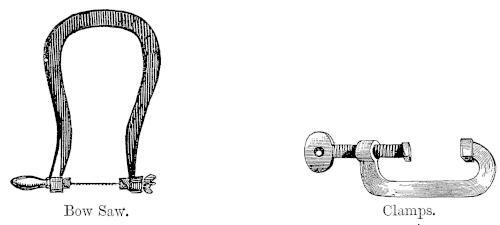

The principal cutting tools used by the Joiner are, saws, planes, and chisels.

The saws are of various sizes, and are called rippers, half rippers, hand saws, and panel saws, according to their shape, and the number of teeth to each inch.

Chisel. Gouge. Screw Driver. Screw. Tenon Saw. Narrow Saw.

The tenon saw is used for cutting tenons, or flat slices from the ends of beams, that other beams cut in the same way may rest upon them and yet leave a flat surface. The thick back of the tenon saw keeps the blade from “buckling,” or twisting; as it would be very likely to do while sawing in a horizontal direction.

The dove-tail saw is similar to the tenon saw, but smaller, and with a brass back instead of an iron one. It is used for dove-tailing, or cutting notches in a board or beam, into[40] which projections in another board or beam are fitted, in order that the two may be held together, as we see the sides of a box are fitted to the back and front. Then there is the compass saw, for circular work, and the keyhole, or narrow saw, for cutting out holes.

The planes are used for bringing the edges and sides of beams, boards, or other wooden fitting, to a perfectly smooth surface: the first of these, used upon the rough wood, is called the jack plane; another is called the trying or trueing plane; and a third, the smoothing plane.

Trying Plane. Smoothing Plane. 2-foot Rule. Glue Pot.

The plane, as you will see, is a solid piece of hard smooth wood, with a hole in the centre containing the cutting tool, or, as it is called, the plane iron, which is firmly fixed with a wedge, so that its sharp cutting edge only slightly projects at the bottom.

The wood which is to be smoothed is fixed on the joiner’s[41] bench by means of a screwed board, called a shooting board, and, by means of the handle at the top, the plane is made to slide swiftly along its surface, so that the edge of the tool cuts off a thin shaving.

There are various sorts of planes besides these, used for cutting various parts of the work, but they are most of them of similar construction.

Chisels are either for paring the wood, and are used with the hand; or are intended to cut into the thickness of the wood, and are then struck with a large wooden hammer, called the mallet. The gouge is a curved chisel, used for cutting mouldings or making round edges.

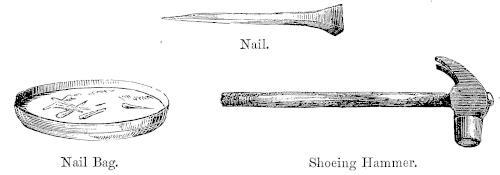

Clout Nail. Cut Clasp Nail. Brad. Spike Nail. Bradawl. Chisel. Gimlet.

The boring tools are the bradawl, the gimlet, and the stock and bit.

The bradawl is a small sharp wire fixed in a handle, and used for making holes to receive large nails, which, if driven in at once by the hammer, would split the wood. Nails are of various kinds, the difference in which may be seen in the[42] engraving. The best kinds of nails are made from thin bar iron, pointed, cut off to the proper length, and the head formed by stamping.

The gimlet is a hollow blade with a screw at the end, and fixed to a cross handle. It is used for boring a larger and rougher hole than the bradawl, for receiving screws, which are screwed into their place by the screw driver, a sort of chisel, the edge or point of which enters the notch in the head of the screw, so that the workman may turn it round.

The bit is a tool not unlike a large bradawl, which fits into a stock or handle. The bits are of various sizes, and are used for boring large holes.

Centre Bit.

The brace and bit, or centre bit, is a tool with a centre and two sharp points, one on each side; it is placed in a bow-shaped stock with a round loose end. This loose end the workman holds firmly, while he places the point of the tool against the wood required to be bored; he then turns the bow briskly round, and the two points revolving rapidly, cut out a circular piece.

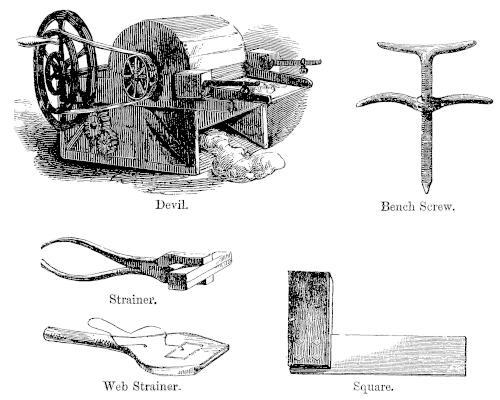

The pincers are used for removing nails from wood, and it is easy to see how they are applied. There are some other tools which belong to the trade of the Joiner, but they are used less frequently, and a description of them will be given when we have to say something of the trade of the[43] Cabinet Maker, whose work resembles the finer part of that which the Joiner does at his own workshop.

The bench (see large cut) is the great table of thick planks supported on a timber frame, at which the Joiner works; it is furnished with a “side-board” perforated with holes to receive a pin, against which one end of the wood on which he is operating rests, the other being firmly fixed in the bench screw.

Pincers.

HOUSE-PAINTING AND GLAZING.

Although we have spoken of the trade of the Plumber separately, and have placed the Painter and Glazier together, it generally happens that the three trades are carried on by the same persons, and you will often have noticed “Plumber, Painter, and Glazier” over the fronts of shops, where leaden[45] pipes and taps, casements, and squares of coloured glass, and specimens of “graining,” or imitations of various woods in painting, are placed for show in the windows, to represent the different businesses carried on.

It is the duty of the House Painter to cover with his colours such portions of the Joiner’s, Smith’s, or Plasterer’s work as require to be protected from the action of the air, which would cause them to rust or decay. He has also to choose the colours which will be best suited for decorating walls and cornices, and generally to apply the proper shades for all the ornaments of the house, and this part of the business, which is called “decorative painting,” requires a great degree of skill and taste in the workman, who may properly be called an artist.

The materials used by the Painter are principally white lead, linseed oil, spirits of turpentine, “dryers,” and putty. White lead, which forms the basis of almost all the colours used in house painting, is prepared by exposing strips of lead to the action of acid; but the Painter buys it ready made, in the form of small cakes, or lumps. This white lead is used in all the under coats of paint, and generally makes the body of most of the colours which are afterwards applied. Unfortunately, while it is in the half-fluid state, when it is used by Painters, it is very poisonous and unwholesome, and many workmen suffer severely in their health from its use; but it will be found that this is often caused by their own carelessness in working, and by the want of personal cleanliness. The Painter should not only thoroughly wash his hands before every meal, but as soon as his work is done should entirely change his clothes, and wash hands and face thoroughly, or even take a bath. Beside this, he should wear, over his working clothes, a[46] coarse linen frock or blouse, which will protect him from the spots of paint, and may be frequently washed.

Linseed oil and spirits of turpentine are used for mixing and thinning the colours; linseed oil is obtained from the seeds of the flax plant, which are heated, beaten, and pressed by machinery, until the greater part of the oil is extracted; the seeds crushed into cakes are then used as food for cattle. Nut oil, or the oil pressed from various kinds of nuts, such as walnuts, hazel and beech nuts, is also frequently used for mixing colours where they are likely to be exposed to the weather, but linseed oil is cheaper and is most generally adapted to the purpose.

Oil of turpentine, which the Painter calls “turps,” is the oil obtained by distilling crude turpentine; and is used by the House Painter to make his colours work more smoothly and freely in the brush, to cause them to dry more quickly, and to take away that shiny unpleasant glare that would otherwise be seen on the surface of paint mixed with linseed oil alone.

It is necessary, too, to take some means to make the linseed oil dry more rapidly than it would in its raw state; or the paint would remain moist and greasy upon the walls for a very long time. For this purpose the oil is boiled, and is then known as “boiled oil,” this is bought ready prepared, the Painter having by him preparations of lead or vitriol, called “dryers,” which he mixes with his colours, after they are made, in order to increase the rapidity with which they set upon the places where they are applied.

The Painter has only a few tools, and these are very simple; they consist principally of the grinding stone, or slab and muller, for grinding his colours; earthen pots for[47] holding the paints; cans for oil and turps; a few tin pots, or open cans and kettles, for colour to be applied to outside places or walls where he has to work on ladders; a palette knife, for spreading the white lead on the stone, or removing the paint to the palette, for fine work, or to the paint pot; and brushes of different sizes.

Slab and Muller. Paint Pot. Palette Knife. Oil Can. Paint Pot. Paint Kettle.

The various colours, which are mostly made from earths and minerals, are purchased by the Painter in powder or small dry lumps, and have to be brought to a fine state, and made quite free from grit, before they can be used.

The slab, or grindstone, is generally of marble or porphyry, and must have a perfectly smooth surface; and the muller is a large oval or egg-shaped pebble, with one end broken off, and the surface made as smooth as that of the slab. A small quantity of the colour which requires grinding is placed on the stone, and moistened with a little oil; and the muller is then worked over it, by a circular movement, until it is gradually driven to the edge of the stone. The colour is then removed by the spatula, or palette knife, and placed in the paint pot.

Paint Brushes.

In this state, however, the colour is too thick to use, and of course requires to be thinned by adding the oil until it is sufficiently fluid.

In painting woodwork, the first business is called “knotting,” that is, removing the turpentine from the knots, which would otherwise ooze and spoil the paint. They are first covered with fresh slaked lime, which dries up and burns out the turpentine; this is afterwards scraped off, and the knots painted with a mixture of red and white lead mixed[49] with glue size, and afterwards with white lead and linseed oil. When dry, they must be rubbed smooth with a piece of pumice stone. The next operation is to put on the “priming,” which is the first coat of paint, composed of red and white lead and linseed oil. The nail-holes, and other imperfections, are then stopped up with putty (a mixture of linseed oil and whiting, made into a paste), applied with the stopping knife; and then the other coats of paint are laid on; three coats being generally considered sufficient; and the last being of the required colour.

Stopping Knife.

The brushes used by the Painter, are either round or flat, the latter being used in varnishing or graining; they are made of hog’s bristles. The smaller kinds of brushes are called tools or fitches, and are used for small surfaces, such as ornaments and mouldings round panels, when the colour is generally taken from a palette—a round slab of wood, with a hole through which the thumb of the left hand passes in order to hold it. The brushes must never be allowed to get dry, but when not in use must be kept in water: it is always best to keep a brush for each colour. Another part of the Painter’s business which requires more skill, is graining and marbling; or the imitation in colours of the marks and grains of various kinds of wood, and the veins and spots in marbles. This is of course a part of the trade which requires a knowledge of the thing to be imitated, and great care and taste in doing it well.

Graining is generally done with “distemper colour,” that is a kind of paint in which whiting and size are used instead of white lead and oil, for the basis of the colour; but the colours depend on the sort of grain to be imitated, and they are applied in various ways and with different sorts of brushes, some of the colour being occasionally removed with a piece of wash leather, in order to give the appearance of the light marks seen in the “heart” of the wood. The appearance of the “grain” of the wood is effected by the graining comb, a comb with short thick straight teeth, which is drawn along the paint in a wavy line.

Graining Comb. Painter’s Brush.

Marbles are imitated in oil if it is outside work and exposed to the weather, but for inside work distemper colour is frequently used.

Occasionally walls are coloured in distemper, and it then frequently happens that a pattern or some ornamental design is painted in the centres of the panels, or round the mouldings. This is a part of the Painter’s trade which requires much skill, and a knowledge of artistic drawing and design.

Varnishing is an operation requiring great care to perform it properly, since it is necessary not only to choose the right kind of varnish, but also to apply it to the surface of the paint with a light but firm hand. Varnishes are made of gums or resins melted, spirits of wine, oil of turpentine, or[51] strong white drying oil. The hard varnishes dry rapidly, and are made of the harder kinds of gums, such as copal, mastic, &c., and the soft of Canada balsam, elemi, turpentine, &c. The most useful for the House Painter are those of copal, linseed oil, and turpentine.

The brushes used in varnishing are generally flat, so as to enable the workman to lay an even surface on the work. Varnishes are usually kept in wide-mouthed bottles; from which they are poured into little tin pans with a false bottom above the real bottom, the space between the two being filled with sand. The use of this is that when the pan is placed over the fire, the sand becomes heated, and the varnish is kept a long time from becoming chilled.

THE GLAZIER.

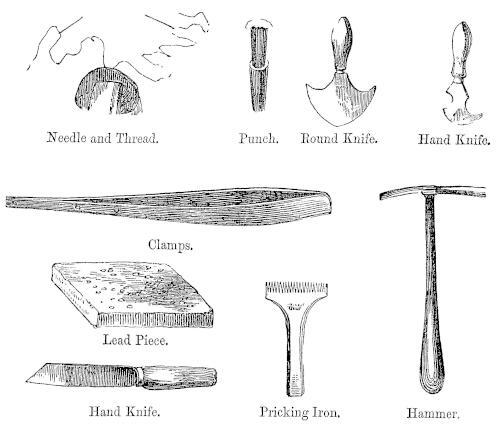

Glazing Knife. Hacking Knife. Chisel Knife. Clicker’s Knife.

The trade of the Glazier, though now very important, was unknown in this country till the eleventh century, and even long afterwards the use of glass for windows was extremely rare; pieces of horn, and oiled paper, supplying its place in almost every building except palaces and[52] churches. As we have here to do with the Glazier, and not with the manufacturer of glass, we need say little about the method of making the materials used; so that it will suffice to know that the “crown glass,” mostly sold for windows of houses, is composed principally of white sand, pearlash, and saltpetre. This glass the Glazier purchases in sheets of a circular form, each of which is called a table, since the mode in which it is made renders such a shape necessary; and the first thing he has to learn, is how to cut out square pieces of the proper size without wasting much of the round edge. The glass when cut is fixed either into lead work or sashes; the former of these is the oldest description of glazing; and in the common kind the leaden frames are soldered together, so as to form squares or diamonds; the sides of the grooves in which the glass is placed being soft enough to bend back to receive the panes, and then bend back again to hold them firmly. In wooden[53] sashes, such as are now commonly used, the space or frame for each pane of glass is “rebated,” that is, it has outside a small groove all round to receive the pane, and a ledge against which it rests. In this “rebate” each square of glass is placed, and then firmly bedded and fastened smoothly with a rim of putty filling up the groove.

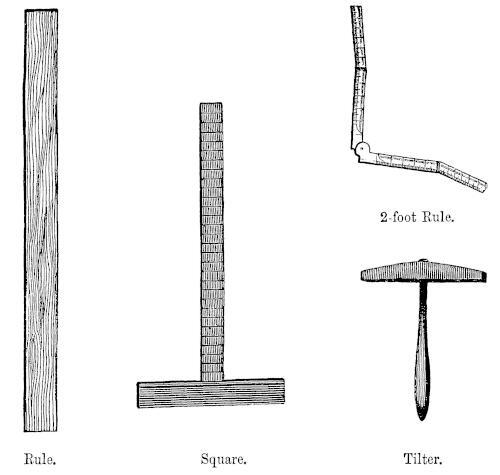

Rule. Square. 2-foot Rule. Tilter.

The Glazier uses a hacking knife for cutting out old putty from broken squares; and the stopping knife, or glazing knife, for laying and smoothing the putty.

For setting glass into lead work, the setting knife, or chisel knife, and the broad-bladed knife is used.

As much of the Glazier’s work is done outside the house, he is sometimes compelled to use a board which is fastened with screws, and projects from the window so that he may sit astride on the outside. No one should ever attempt this where the sash can be easily taken out and the work done inside.

Diamond. Pincers.

The rest of the Glazier’s tools are a square, and a straight edge rule for cutting against, a two-foot rule, and compasses for measuring; pincers for breaking off the edges of glass that have been partially cut through; and the diamond, which is used for cutting, and is his principal tool. This is made of a small unpolished diamond fixed in lead, and fastened to a handle of hard wood.

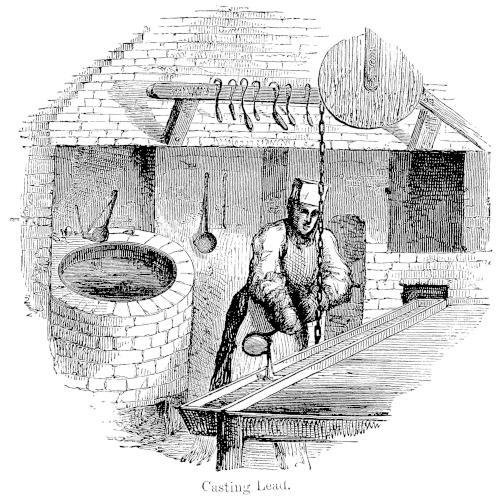

Casting Lead.

In trades connected with building, the work of the Plumber is of so much importance that it must come next to that of the Bricklayer, and the Carpenter. At one time the Plumber (who takes his name from the Latin word for lead[2]) was principally employed in making leaden roofs of churches[56] or large public buildings and in forming casements for windows; window frames being then made of strips of lead soldered or riveted together and holding the little diamond-shaped panes of glass between their edges. In those days all the water used in the house was carried from the well or from the conduit in the main street, or was brought in casks set upon wheels from the nearest running stream: while rain-water for washing was collected in tubs or vats as it ran off the roofs. Not much more than a century ago the poets wrote of the misery of the streets of London on a wet night, when there were no waste pipes to carry off the rain from the overcharged gutters on the tiles, and nobody could venture out of doors without being half drowned by the sudden discharge of a shower bath from some overhanging gable. Then, as there was no proper system of pipes for carrying off the wet, there was very little drainage except by means of open gutters, and the bye-ways, as well as some of the principal thoroughfares and large houses, were extremely unhealthy.

[2] Plumbum.

We are not quite perfect even yet in these respects, and there are still neighbourhoods in London where a few Plumbers might be able to make vast improvements; but we are a great deal better off than our great grandfathers were. The Plumbers do not make quite so many leaden casements as they made in the olden time, but they are well employed in constructing roofs; carrying water into houses by means of leaden pipes; making cisterns to contain a good supply of it, and providing other pipes and gutters for conveying all the dirty water and drainage into the sewers that are under the roadway, where it runs quite away from the streets, and (in London at least) goes into the sea from near the mouth of the Thames at Erith.

Ladle. Grate. Soldering Iron.

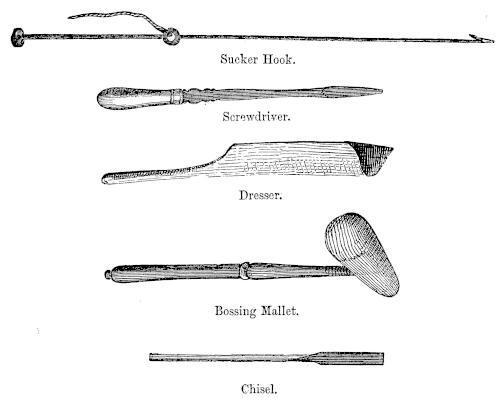

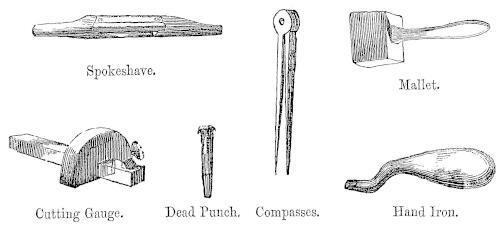

Now as the Plumber has to do a great deal of his work in roofs and other places where he is liable to fall, he should be clear-headed, and able to go up a ladder or look over a ledge at a height from the ground without being afraid, and this is all the more necessary because he has to handle tools, and sometimes to pour melted solder out of a hot iron ladle while he is at his work on these places. For the purpose of melting the solder he has to carry his fire grate and melting pot with him to some place near where he is at work, since unless the solder can be used rapidly it cools, and will not make a sound joint. The rest of the Plumber’s tools are the pouring stick for applying the melted solder in the places where it is required, the soldering iron which is made red-hot, and passed over the soldered joints to smooth them and make them all firm and sound; the chisel, shave hooks, drawing knife, and chipping knife, for cutting the lead and[58] scraping it on the surface, or at the edges that are to be fastened together; the hammers and mallets for beating the lead into shape and flattening the ridges, the bossing mallet and dresser for bringing the sheet of lead to a proper shape, and forming it over the ridge of a roof, the chased wedge, the screw-driver, the dunring and the turnpin for various uses in making roofs, laying down leaden pipes and fixing taps, and the sucker hook used in repairing or fixing pumps when the part of the pump called the sucker requires to be rectified.

Pouring Stick. Chipping Knife. Dunring. Drawing Knife. Chased Wedge. Shave Hook. Turnpin. Shave Hook.

There are other tools beside these, such as planes for making the surface of the lead smooth and even, gouges and centre-bits for circular openings in the lead to receive nails[59] or clamps, measuring rules and compasses, and pads of carpet or cloth to hold under a pipe when it is being soldered, that the solder may be pressed round the joint before it cools, and without its dropping on the ground.

Mallet. Hammer.

Plumbers now buy their sheet lead as well as their leaden pipe at the warehouses, but those in a large way of business formerly cast the lead themselves. For this purpose they used a casting table, which is a great wooden bench about six yards long and two yards wide, made of smooth planks, and with a raised wooden frame round the edge. On this table the Plumber spreads a layer of finely-sifted sand, which was made level by a strike—a flat piece of wood with two handles—drawn from end to end of the table; after this the surface was made still more smooth by a planer, which was a flat plate of copper fastened to a handle.

Sucker Hook. Screwdriver. Dresser. Bossing Mallet. Chisel.

A trough called the pan ran along the whole length of the table, and into this the melted lead was poured from the melting pot. There were two ways of making the sheet[60] lead: one of them was to tilt the trough up, and pour out the lead on to the table, two men immediately passing a wooden strike over it so as to spread it evenly over the whole surface. In this case the thickness of the sheet of lead depended on the distance between the edge of the “strike” and the surface of the sand. Another way was to have a narrow opening all along the bottom of the trough, the trough itself moving from end to end of the table as the lead flowed out. When this method was used the thickness of the sheet depended on the size of the opening, and the rapidity with which the trough was moved along the table.[61] Neither of these methods are now used, the lead being rolled into sheets by machinery.

Water-pipes are made by lead being cast in moulds with a steel rod passing through their middles, according to the size required. The lead is poured into the space between the rod and the mould. After it is cool the rod is drawn out by machinery, and the mould which is made in halves is opened and the pipe taken out. The pipe is then much thicker and shorter than is required for use, but it is afterwards drawn between powerful iron rollers with grooves cut in their surfaces, an iron rod being again placed inside it. As these grooves gradually decrease in size, and the pipe is drawn through several, it is very considerably lengthened, and at the same time diminished, in thickness, by the time the operation is finished. Another method of making lead pipes is by the use of the forcing pump, which pumps the melted metal out of the boiler into a mould containing a “mandril,” or pipe of the required size. Pipes made in this way do not require to be rolled.

Forcing Pump.

The work which the Plumber is called upon to do on the roofs of houses requires experience before it can be properly performed. The foundation of the roof which is to be covered with lead is made either of boards or plaster, so that the surface may be even, and if it be of boards they must be thick and well seasoned to prevent their warping.[62] The foundation slopes a little in order to carry off the rain towards one end. When the roof is so large that it needs two widths of lead, there are three ways of joining the edges of the lead together: one is by fastening to the roof long slips of wood (flat at bottom and round at top) at the places where the lead will be joined. Over these strips the edge of the first sheet of lead is folded and hammered down quite close, then the edge of the second sheet is folded and hammered over that, so that water cannot get between them. This is called “rolling.”

Another method is to bring the two edges up just as though they were to be sewn together, then to fold them tightly one over the other, and hammer them down: this is called “overlapping,” but it is not so good as rolling for keeping out the rain.

The third way is to solder the edges together: the solder, which is in constant use by the Plumber, being a metal made by mixing lead and tin together. These two metals when mixed adhere very strongly to the lead that they are meant to join, and the surface to which they are applied is made hot enough to unite with the solder by means of the soldering iron, while very often a little resin, borax, or tallow is placed on the surface of the lead to cause it to combine more rapidly with the molten metal.

Besides the fixing of roofs the Plumber makes leaden cisterns, fixes rain-water gutters, and waste pipes, and arranges taps and drains; and in some of these operations he will use zinc instead of lead. Not the least important part of his business, however, is the construction and arrangement of pumps, and for this purpose it is necessary that he should study mechanics, and those branches of science which refer to the properties of water, and to the[63] laws which govern the air and other fluids. He is always the best workman who goes to his business with a knowledge of the natural laws and scientific facts connected with it, and a very little study will save a world of blundering; during which the ignorant man will remain a labourer, because it takes him half a lifetime to learn his business.

GASFITTERS AT WORK.

As there are now few large houses which are not lighted by gas, the trade of the Gasfitter is one of considerable importance; and though the materials used are generally bought ready made from the Brassfounders, the glass-works, the Ironfounders, or the lead warehouse, considerable skill is required, as well as some taste in properly adapting the[65] chandeliers and burners, and skilfully adjusting the tubes and pipes so that they may easily be repaired, or any escape of gas quickly detected. The various tools used by the Gasfitter are simple enough, but careful practice is necessary for their proper use; and, as any flaw or imperfection in the work may lead to very dangerous consequences, all the operations should be thoroughly tested, and every joint and fitting in the various parts made sound and strong.

Before the gas is taken into a house, or as it is called in the trade “laid on” in the house, it is of course necessary to obtain the permission of the Company to whom the works where the gas is made belong, and to agree to pay for the quantity that is burnt, which is charged by the thousand cubic feet, and varies in price according to the cost of the coal from which it is made, and the difficulty of conveying this coal to the works.

Spade. Crowbar. Rammer.

The first operation is to take up the roadway in front of the house, in order to connect the pipe which is to convey the gas to the meter with that which conducts it from the works to the different streets of the neighbourhood. For this purpose the spade and crowbar are necessary, while[66] sometimes the pickaxe also has to be used; and the rammer serves to beat the earth down more closely after the pipe is laid.

Brick Bit. Brick Auger.

The pipe which is joined to the larger pipe, or main, is generally of iron, and is made with a screw and socket, that it may not be easily displaced by the pressure of the roadway or footpath, and this, passing into the basement of the house, supplies the gas to the meter. The meter is a mechanical contrivance, which is so constructed that the quantity of gas passing through it is registered by a plate something like a clock face, with a hand to point to the figures which represent the number of cubic feet consumed. There are different kinds of meters, and the construction of them varies very considerably, but they all answer this purpose: so that when the inspector visits the house once a quarter he may directly see what quantity is to be charged for. The pipe leading from the meter is fitted with a strong tap, by turning which, all the gas may be shut off from the tubes that convey it to the different burners in the house, and from this pipe the smaller pipes (made of a sort of solder or of lead) are taken to the various rooms. In order to carry the tubes through a wall, it is necessary to use the brick bit and the brick auger for boring a hole to receive it, while to support it against a wall or along the top of a[67] ceiling the Gasfitter uses wall hooks, the hammer and the tongs for holding and bending the pipe to its proper direction. In kitchens and basement rooms the pipe is generally carried from the meter up the wall and along the ceiling to the place where the burner is to be fixed: but in upper rooms the pipe is taken up the house wall, and carried under the flooring of the room above to the centre of the middle joist, where a hole is bored quite through the ceiling of the room below. For this purpose the twisted auger is generally used; and for the preliminary work of taking up the floor and cutting a groove in the joist to receive the pipe, that it may not be injured by the pressure of the boards above, the saw and the hammer are required.

Wall Hooks. Nuts. Grease Pot. Hammer.

Twisted Auger. Saw. Blowpipe. Tongs.

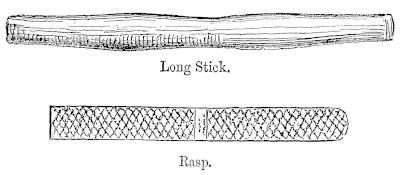

Waxed Rushes. Rasp.

Of course one length of pipe is not sufficient to go to any great distance, and a joint has frequently to be made, the solder used for this purpose being so easily melted and so readily combining with the pipe itself, which is of almost the same material, that the flame from prepared tow blown to an intense heat by the blow pipe is sufficient for the purpose. The rasp is used for filing the surface at the ends of the pipes where they are to be joined, and the waxed rushes to try the joints in order to see that there is no escape of gas through some small hole. When the pipes are all laid and brought to their proper positions the fittings are fixed. Those which descend from the centres of ceilings are generally called chandeliers, and consist of a tube of metal fastened to the gas pipe, the end of which coming through the ceiling is furnished with an iron screw to fit the end of the tube. This tube is placed within a larger tube, from the bottom of which a still smaller one passes within the first. The gas therefore descends the tube from the ceiling, and enters the smallest tube, which communicates with the burners that spring from the largest. The larger tube is intended to receive water, in which the end of the first tube rests, so that the gas is prevented from escaping, while by a nice adjustment of weights running over pulleys attached to the larger, the burners can be raised or lowered, as one tube slides within the other (see large cut). The taps are placed at the burners to turn on or turn off the gas as it is required, and in order to fix and screw these, as[69] well as to fasten joints in the fittings by means of screw nuts, the pliers and the wrench are used.

Wrench. Tow. Tap. Rimmer. Clamps. Pliers. Drill Stock.

The clamps are a sort of vice with grooved holes, for holding the taps and metal joints firmly while they are filed or otherwise prepared; the drill stock is used for boring small pipes in order to make a branch to some other direction, and the drill brace is intended for boring the main pipes, under which the large hooks are placed while a stock and bit attached to the upper screw makes the hole; the ordinary braces are fitted to a ratchet or cog wheel at[70] one end, and are also used for making incisions by being worked backwards and forwards.

Drill Brace. Braces. Stocks and Dies.

The several kinds of burners are pierced or cut in such a way as to make the flame from the gas of different shapes, such as fish tail, cock spur, star, or argand, the names of which tell pretty well in what shape they appear. Small rooms are sometimes fitted with “telescopes” instead of chandeliers, the telescope being one tube sliding within another, and the space carefully filled with a properly adjusted cork or some other flexible and impervious substance.[71] Bedrooms, and apartments where light is required at the walls or chimney pieces, are furnished with brackets, which either simply project from the wall, or are made with an arm moving on a ball and socket joint. The manufacture of the various portions of the apparatus used in gas fitting will be mostly found described under the trade of the Brassfounder.

GASOMETERS.

Very few of the readers of this book will remember the appearance presented by London streets before the introduction of gas; when all the thoroughfares were darker than even the commonest streets are now, and the only light emanated either from the shop windows or from dim oil lamps, which the rain or the wind would frequently put out, even when they did not burn out of themselves for want of being trimmed and replenished. A century ago these oil lamps were quite insufficient to light even the main streets, and people who walked out at night generally[73] hired a “link boy” to light them as they went, with a great flambeau of hemp and pitch, which smoked and smelt insufferably. The nobility and gentlefolks who rode in carriages were also attended by footmen with flambeaux of a better sort, and outside the doors of some of the oldest houses in London there may still be seen the great iron extinguishers attached to the railings, where the torch-bearers put out their lights till it was time to escort their masters and mistresses home. The poet Gay, who wrote the celebrated fables, describes the link boys, and gives them rather a bad character for so often being connected with the bands of thieves and footpads which infested London streets, and robbed people with impunity in the dark. He says:—

Long before this, however, the inflammable nature of the vapour which streamed from burning coal had been observed by scientific men, and it was thought by many people that some method might be invented for making this gas useful for the purpose of lighting streets or houses. It had also been observed that the air suddenly escaping from the shafts of coal mines was often highly inflammable, and some experiments were made in the distillation of coal as early as 1726. In 1765 Lord Lonsdale proposed to the magistrates of Whitehaven to convey the gas from the neighbouring mines through pipes for lighting the town.

A number of eminent men afterwards made experiments with gas, but no decided practical result followed until a[74] Mr. Murdock, of Cornwall, began to manufacture gas for lighting his house and offices at Redruth. In 1798 the same gentleman used gas for lighting the Soho Foundry, where four years afterwards a public exhibition of the new invention was made by means of an illumination to celebrate the proclamation of peace.

In 1803 a gentleman named Winsor first publicly showed at the Lyceum Theatre, in London, a system of illumination by gas, which was the commencement of our present method of lighting our streets and houses; and after great difficulties and various experiments, a company was formed for the purpose of carrying out the undertaking of superseding the old oil lamps and making use of the new invention. The premises of the company and their factory were situated in Pall Mall, where the Carlton Club now stands, and the lights first appeared from the corner of St. James’s Street to the Haymarket, while several jets were placed in front of Carlton House, the residence of the Prince Regent, afterwards George the Fourth.

By slow degrees, and by the assistance of Mr. Clegg, an eminent engineer, the manufacture of gas improved, and in 1814, when the allied sovereigns visited this country, and a general illumination was ordered, a magnificent pagoda in St. James’s Park was erected for the exhibition of the new light. The following year Guildhall was fitted with gas burners; and, although it had been predicted that the new invention would ruin the navy by superseding the use of the oil brought by the whalers, and though some people declared that it was only a scheme for blowing up London, the success of these experiments led to its rapid adoption in most of the large towns of Europe.

It will now be necessary to say something of coal, of[75] which more than 400,000 tons are used every year for the manufacture of gas in London alone.

The name coal was originally given to any substance used for fuel, and the use of mineral coal, or, as it was formerly termed, sea-coal, from the fact of its being brought by sea, has not prevailed for longer than 200 years. Coal is found in this country in extensive deposits called coal-fields, the most important of which are:—1. Those of the great northern district, including the coal-fields north of the river Trent. 2. Those of the central district, including the Leicester, Warwick, Stafford, and Shropshire coal-fields. 3. Those of the western districts in North Wales, South Wales, and Gloucester. The coal occurs in a number of layers, or beds, termed seams, and these are separated from each other by layers of slatey clay, called shale, and coarse, hard sandstone, known as grit.

The seams of coal are mostly comparatively thin, but varying from a few inches to six or eight feet in thickness, and underneath the layers is usually found a bed of mountain limestone extending beyond the coal-field, and rising to the surface of the ground around it.